Table of Contents

Approved

If you have any problems with the puncher on your PC, we hope this guide can help you.

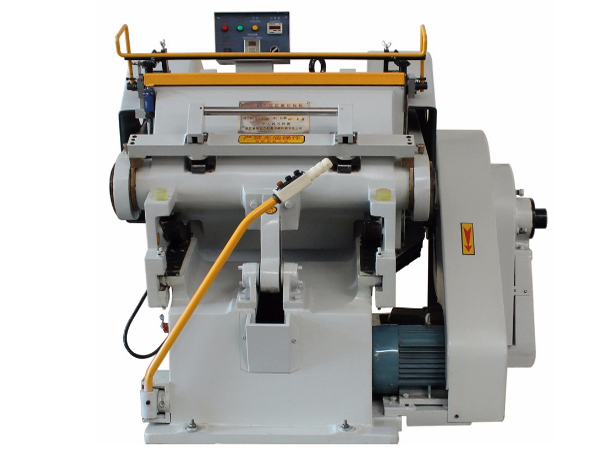

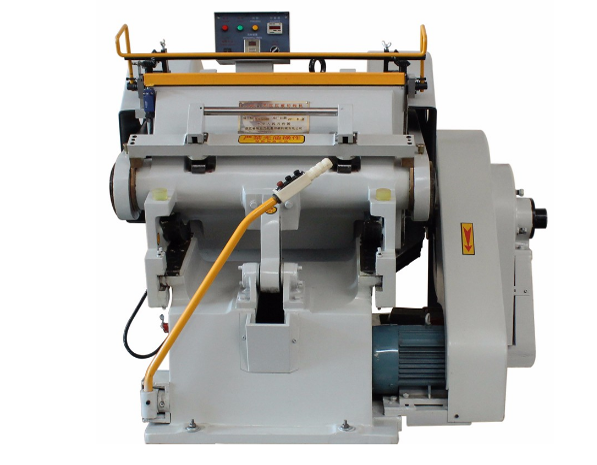

Die cutting machines are generally used more often than ever as the demand for carton boxes for services has increased due to e-commerce. However, as many manufacturing companies are just getting started with a real machine, many are struggling with machine malfunctions.

The loss of material directly affects the entire operation, in particular the delivery time. This results in high operating costsand lower income.

SBL Machinery lists the most common rock drill problems and how to fix them yourself.

1. Matrix Break

Cutter bar cutting tools may break due to overuse, improper maintenance, or material that is too thick. In this case, it is better to take the car to a service center. Some car owners also fix the problem by soldering broken razors. However, this solution is short at best and dangerous at worst. Blades can break again, and much larger blades can cause problems with your performance.

Approved

The ASR Pro repair tool is the solution for a Windows PC that's running slowly, has registry issues, or is infected with malware. This powerful and easy-to-use tool can quickly diagnose and fix your PC, increasing performance, optimizing memory, and improving security in the process. Don't suffer from a sluggish computer any longer - try ASR Pro today!

Broken waste requires a suitable repair technician. The specialist will weld and anneal the crack completely, restoring the strength and durability to the blades and shape.

2. Inappropriate Cutting Results

For stamps, use thin materials such as parchment, parchment, or imitation paper. This probably makes it easier for the disc to die. If your cube doesn’t fade, use it as stencils or layouts and trace around the shapes with one pencil. You can then carefully cut these shapes with scissors or a craft knife.

Poor punch press maintenance can lead to unstable cutting results. When this happens, expensive paper or paperboard coatings are recycled with waste, resulting in higher production costs. This problemThere are several reasons: blunt and worn dies, almost all dirty cars, or alignment problems.

Leveling and worn cutting blades require quality repairs. But if the malfunction only contaminates one machine, a simple cleaning is sufficient.

Empty the tanks and place the chips and snails in them. Fibers that can be used to make paper and paperboard products are changing the way sheets are stacked. The slightest change in the preparation of the sheets can lead to inaccurate shapes and folds.

3. Offset Blades

The blades of the punch press can be misaligned due to frequent repetitive motion, resulting in crooked and thick cuts.

Again, the alignment issues are best left to professionals. Calibrating the machine and knives is difficult and requires business experience. You can view programmed locations and instructions in a browser, for example:

4. Dented Or Deformed Blades

Cutting knives will dent when worn, so they can be used to cut thick stacks. If you are using a machine with worn or deformedwith blades, the results will be worse. Edges may fray unevenly or require you to delay the process. This problem occurs due to undesirable additional operating costs.

The blade needs to be replaced. Use one with the same specifications as the first one, or ask your vendor if an upgrade is possible.

5. “Fluffy” Edges

“Fuzzy” edges are more common on traditional sheets of paper than on cardboard products, but they are still a recurring problem when someone has a poorly maintained machine. Pile occurs when the cutting blade is not sharp enough to clean every cut of material. We cut out our own leaves, the edges of the object are frayed or “fluffy”.

As with dented and / or warped blades, you need a great replacement so that your customized alternatives don’t fray around the edges. Call a technician for more affordable alternatives.

6. General Wear

The outer edges of the razor blade will tarnish if the wind turbine iswill not still come into contact with metal. At the same time, the free sale between the anvil and the tool cylinders must be properly calibrated. Otherwise, the dies will be too damaged, which will speed up the machining and tearing process.

The only solution here is to unambiguously attach the back nozzle to fix this. The technician will weld and restart the nozzle to return it to normal.

7. Dotted And Dark Lines

Broken and dark lines are image defects of non-standard products caused by faulty punch presses. Break lines are wrinkles at the ends of paper or cardboard that occur when the die pressure is too high.

On the other hand, black lines can still occur due to improper blade alignment, incompatible stamp prints, or lack of voltage. Under these conditions, folds in the material appear as dark lines.

You can avoid most of these dilemmas by following the correct punching program. If your machine is not working properly, contact immediatelywork with a technician to avoid production downtime.

SBL machines are at your disposal to produce world-class folding machines for cutting and other packaging materials whenever you need to meet your business needs. We offer a number of options to meet individual requirements, which are usually required by different manufacturers. We also offer cleaning and renovation services so you can maximize the life of your new investment.

Of course, fill out our service form if your machine needs repair or if you have any questions, call SBL Machinery on +886 2 2680-2199 or use our feedback form.

The software to fix your PC is just a click away - download it now.

The handling is simple – you can see that the stamp is placed on top of your stamped parts (such as paper or cardboard), which is often marked, and then the whole thing is usually pressed between two plates. Then the finished “sandwich” is fed into the punching machine itself, where they usually cut the pattern one by one – it’s that simple!